Specialty Tubes, Perforated Cores and Welded Assemblies

Industry experts since 1976.

We’re at the CORE of Innovation

Beverlin Specialty Tube provides perforated tubes and cores for filtration, exhaust and welded assembly solutions. From our home base in Grand Rapids, Michigan, we source materials from DFARS-approved countries and deliver finished perforated products and assemblies to our valued customers around the globe. Our experience, deep market knowledge, and exceptional customer service enable us to deliver world-class precision-quality perforated solutions.

We have an ISO 9001:2015 certified QMS and employ a certified Project Management Professional (PMP) to help carry out a flawless execution.

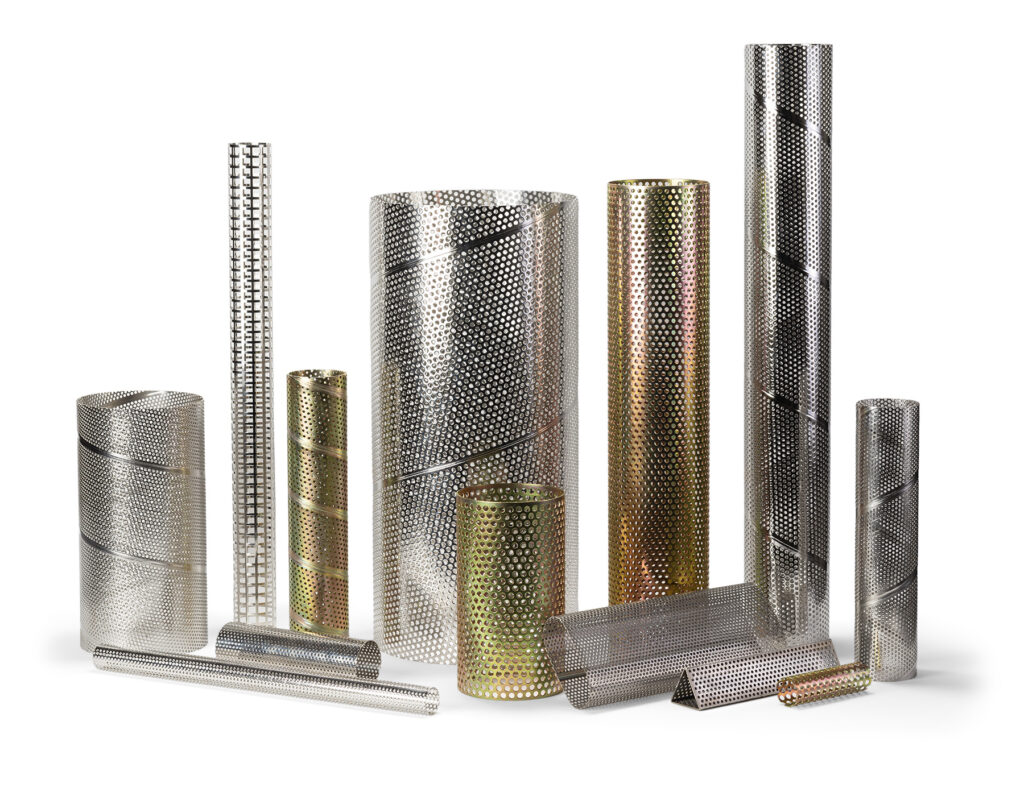

Products

At Beverlin Specialty Tube, we offer an exceptional line of perforated filter cores, exhaust housings, flanges, cones, end caps, and strainer baskets in nearly any perforation pattern and hole size, including custom patterns. As your one-stop solution provider, we also offer a range of value-added services that customers can access to streamline their projects. View our extensive list of products and value-added services.

Filtration

- Center Cores

- Welded Assemblies

- Strainer Baskets

Welded Assemblies

- Machined Components

- Custom Fabrication

- Value-Added Services

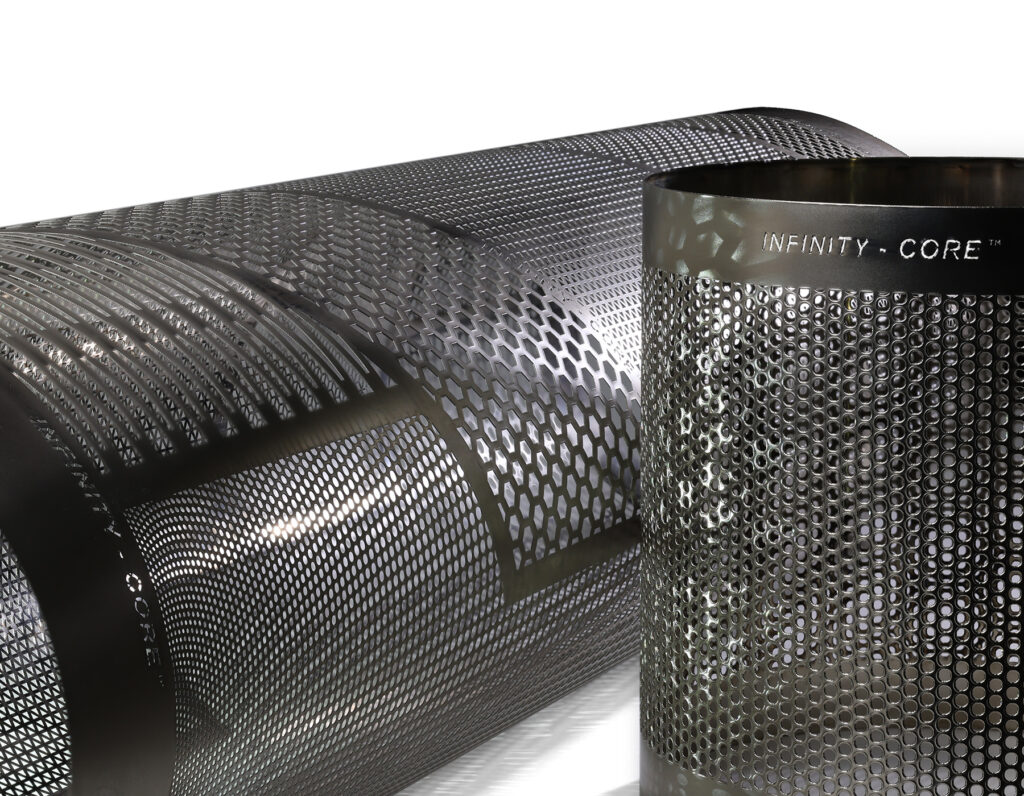

Infinity Core™

- Seamless 99% Nickel Core

- Harder & Stronger than Stainless Steel

- Corrosion-Resistant

Exhaust

- Tubes

- Cones

- Flanges

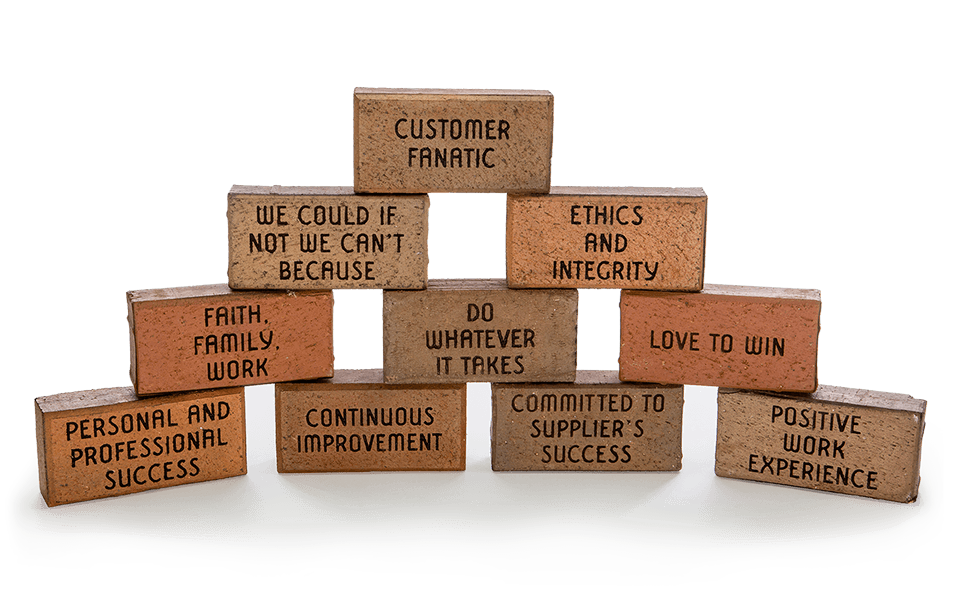

Our Difference

We are driven to be different by a unique set of values we call Leadership Covenants. These Covenants are displayed for team members as a constant reminder of what is expected and rewarded in our workplace.

Capabilities

We offer in-house tooling and a staff of Journeyman and Certified Welders. These skilled resources allow us to be responsive to our customers’ diverse and creative needs. We can manufacture almost anything. We have a zero PPM mindset and strive for perfection. Our quality management system ensures the integrity of every product and service we deliver.

Contact Us

Are you an engineer or buyer with questions about perforated tube production or the right products to fit your design? If so, contact us to speak to one of our experts.

Let’s Connect

Contact us with with any questions you may have or get your next project with Beverlin started by submitting a quote today.