Products

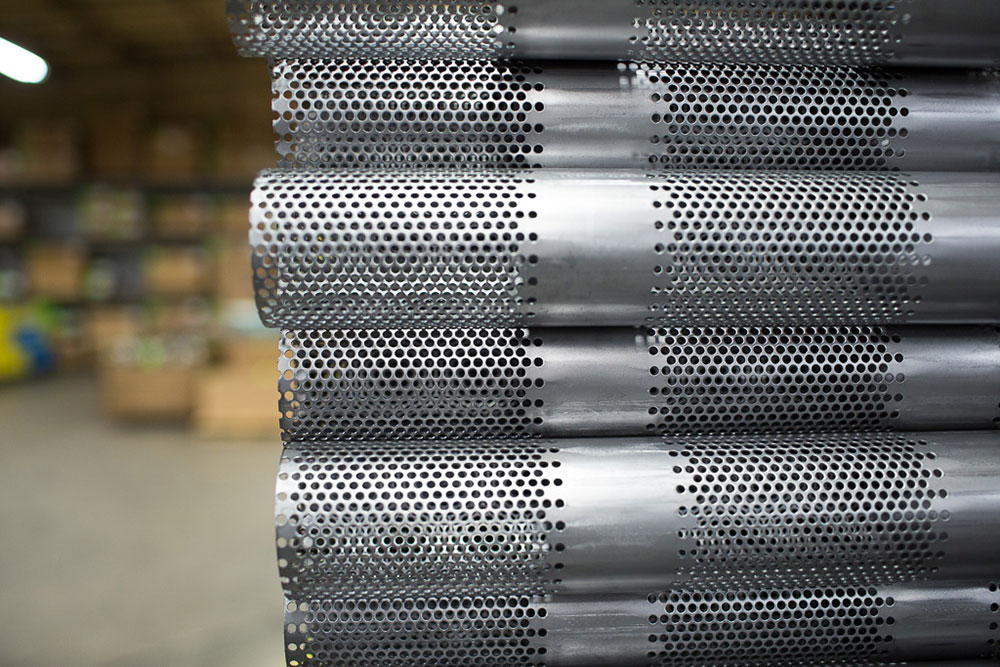

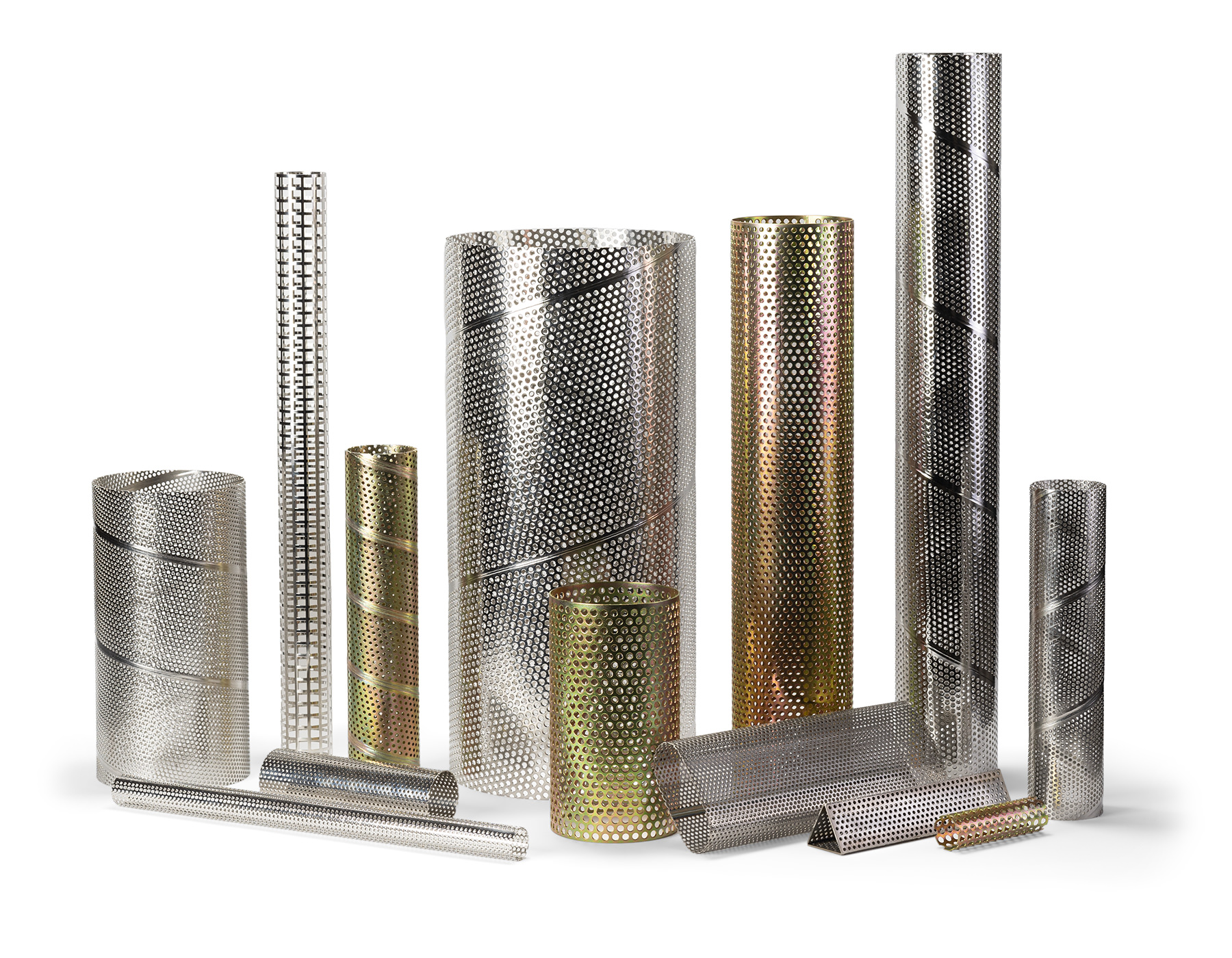

Versatile Perforated Products and Custom Perforation Patterns

Our exceptional range of perforated products—which includes filtration cores, exhaust housings, flanges and end caps, welded assemblies and strainer baskets—is available in nearly any diameter, length, perforation pattern and hole size. We specialize in creating custom perforation patterns tailored to your specifications. View our list of extensive product offerings and value-added services.

Exhaust

- Tubes

- Cones

- Flanges

Filtration

- Center Cores

- Welded Assemblies

- Strainer Baskets

Welded Assemblies

- Machined Components

- Custom Fabrication

- Value-Added Services

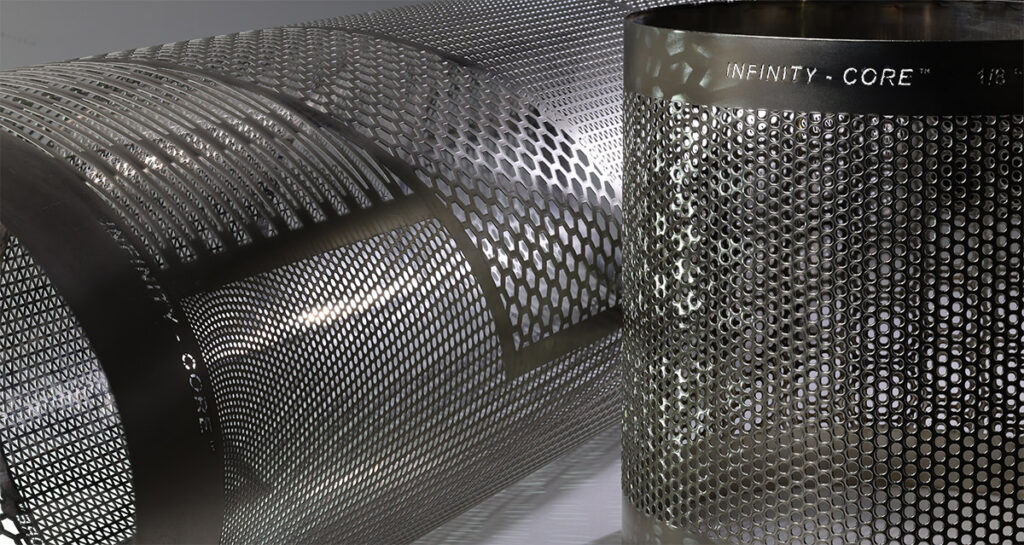

Infinity Core™

At Beverlin, we’re always seeking innovative solutions. Infinity Core™ isn’t just a new product for 2024, it’s a revolution in filtration. A seamless nickel construction tube, Infinity Core far surpasses the strength and corrosion resistance of stainless steel, making it ideal for harsh environments.

- Seamless construction core

- 99% nickel composition

- Corrosion-resistant

- Harder and stronger than stainless steel

- Patented manufacturing process allows for endless designs

- Hole size down to 80 micron (.003’’) – depends on material thickness

- Material thickness from .008’’ – .035’’

- Diameter tolerance is +/-.0005’’ (air gauge measurement)

- Remains magnetic up to 354°C

Perforated Metal Tubes and Filter Cores

Our filter cores and drier cores are used in a number of applications:

- Industrial Filtration

- Aerospace

- Inlet Separation

- Fracking

- Defense

- Chemical Filtration

- Fuel Filtration

- Liquid Degassing

- Oil & Gas Harvesting

- Nuclear Cooling Water Filtration

Materials

Our range of options include but are not limited to:

- Stainless Steel

- Carbon Steel, Cold and Hot Rolled

- Duplex and Super Duplex

- Aluminum and Specialized Alloys From 0.018” to 0.12” Thick.